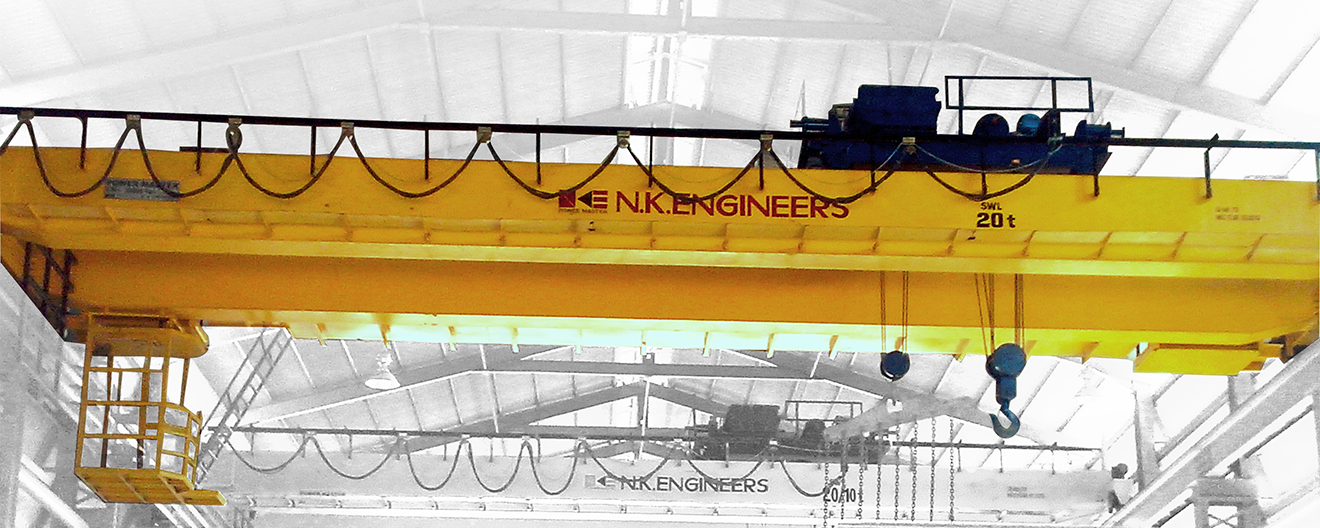

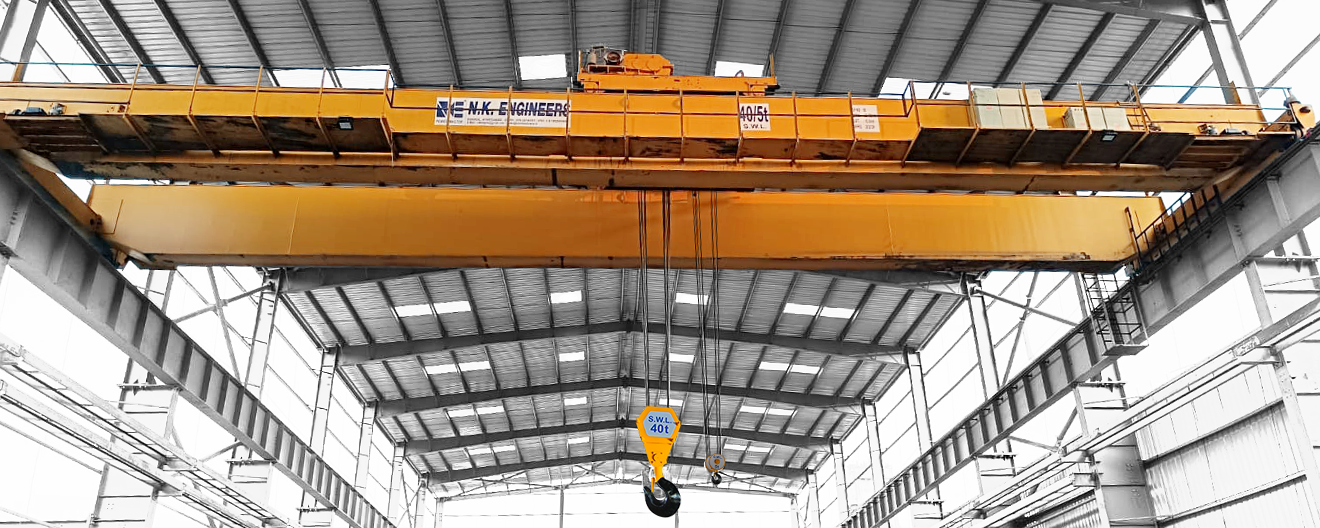

Double Girder E.O.T. Crane

Power Master is leading EOT Crane Manufacturer, Supplier and exporter who design the best products of the market. Our robust cranes are made using a practical design and durable quality material and have a lot of beneficial features. Power Master Double Girder EOT Crane is designed strictly in accordance to IS: 3177-2006, IS: 4137-1985 and IS: 807-1999 up to Class IV, extra heavy duty applications. From design to area of installation and environmental factor to service types, we ensure to apply these standards to all the aspects of manufacturing. These cranes are robust in construction and are customized specifically to meet the customer’s requirements.

Power - Master Overhead Travelling Cranes designed & manufactured in accordance to IS: 3177 & IS: 807 are available in medium duty and heavy duty classification with below configuration. (We also make heavy duty class IV cranes for steel plants as per IS : 4137-1985)