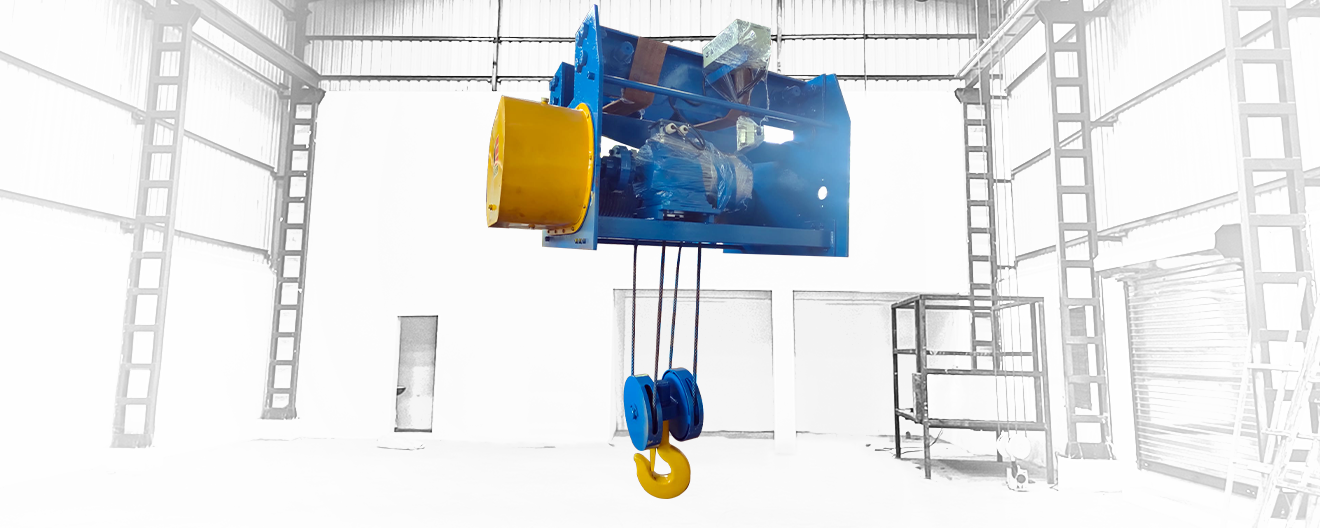

Wire Rope Hoist

Power Master Electric Wire Rope Hoists are designed as per IS 3938 – 1983 (R2012) and are suitable for light and medium-duty applications.

Heavy-duty fabricated Structure for hoisting & trolley, Cast iron Gear Box Housings with High Precision-cut Oil Cooled Helical internal gears & Pinion makes this machine the most demanding Machine in the industry. All Standard models of Electric wire rope hoists are designed with M5 & M6 rated Gearboxes to improve machine performance. We also offer specially build M8 duty wire rope hoist for continuous usage.

Heavy Duty ball & Spherical Roller Bearings are provided for Gear Box and Wire rope Drums. The Electric wire rope hoists are offered with VVVF drives and designed for long life and maintenance free operations.

Power - Master Electric Wire Rope Hoists designed & manufactured as per IS: 3938 are compact and modular with easy in operation & maintenance.